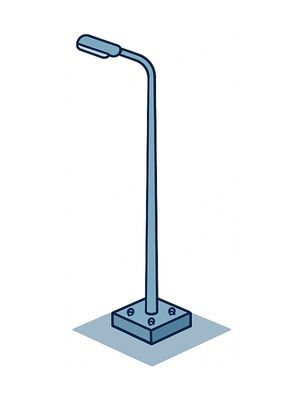

Advanced Engineering with Trusted GRP Poles

Enhance your industrial and commercial spaces with our premium GRP products — engineered for exceptional strength, lightweight design, and superior resistance to corrosion and chemicals. Designed to deliver lasting performance and safety, our GRP solutions meet the toughest industry demands with ease.

Why Choose Our GRP Poles?

| SR. NO. | Length (mm) | Top OD (mm) | Bottom OD (mm) | Avg. Thickness (mm) | Test Load on Top (KG) |

|---|---|---|---|---|---|

| 1 | 3000 | 76 | 126 | 4 | 200 |

| 2 | 4000 | 76 | 143 | 4 | 200 |

| 3 | 5000 | 76 | 160 | 5 | 200 |

| 4 | 6000 | 76 | 176 | 5 | 200 |

| 5 | 7000 | 76 | 193 | 6 | 200 |

| 6 | 8000 | 76 | 210 | 6 | 200 |

| 7 | 9000 | 76 | 228 | 7 | 200 |

| 8 | 10000 | 76 | 245 | 7 | 200 |

Note: Dimensional tolerance in linear ±20 mm.

| Property | Test Method | Units |

|---|---|---|

| Specific Gravity | ASTM D 792 | 1.30–1.80 Kg/m³ |

| Glass Content (% by weight) | ASTM D 2584 | 45.0–55.0 % |

| Water Absorption | ASTM D 570 | < 0.5% |

| Tensile Strength | ASTM D 638 | 200 ± 50 MPa |

| Flexural Strength | ASTM D 790 | 250 ± 50 MPa |

| Compressive Strength | ASTM D 695 | 200 ± 50 MPa |

| Yield Strength | ASTM D 638 | 200 ± 50 MPa |

| Modulus of Elasticity | ASTM D 638 | 1500–25000 MPa |

| Feature | Composite Poles | Steel Poles |

|---|---|---|

| Weight | Specific weight ~1860 Kg/m³ (about 26–32% of steel) | Specific weight ~7800 Kg/m³ (3–4× heavier than composite poles) |

| Rusting | Non-corrosive due to inherent material properties | Even after galvanizing or powder coating, rusting begins from inside and at the base |

| Installation | Lightweight; can be installed manually by 1–2 people | Very heavy; requires lifting machinery, increasing installation cost |

| Maintenance | Completely maintenance-free | Requires periodic re-coating or refurbishment |

| Surface Finish | Smooth, integrated surface layer that will not peel over time | Coating may peel due to temperature expansion differences between metal and coating |

| Insulation | Non-conductive; excellent electrical insulation | Conductive; risk of electrical leakage |

| Service Life | 20–25 years; longer lifespan due to corrosion resistance | Shorter lifespan due to rust and degradation |

| Wind Resistance | Withstands wind speeds up to 200 km/h | Not specified |

| Corrosion Resistance | Excellent resistance to water, acid rain, seawater, salty air, and chemicals | Susceptible to corrosion in harsh environments |

| Bendability | Maintains stability after bending up to 25°–30° | Can bend but loses stability |

| Impact Safety | Breaks on severe impact, reducing injury risk to vehicle occupants | Can cause severe damage to vehicles and passengers on impact |

Frequently Asked Questions

GRP (Glass Reinforced Plastic) poles are strong, lightweight, and corrosion-resistant composite structures made by reinforcing plastic with glass fibers. They are used in various applications like lighting, utility, and signage poles.

They offer excellent corrosion resistance, high strength-to-weight ratio, low maintenance, and are safe due to their non-conductive nature. GRP poles also withstand harsh weather and environmental conditions.

GRP poles are ideal for street lighting, garden lighting, solar light installations, flagpoles, CCTV poles, and utility poles.

Yes, GRP poles can be customized in terms of length, diameter, color, and finish to meet specific project needs.

GRP poles are designed to be maintenance-free, but regular inspections are recommended to ensure long-term performance.