Fiber Reinforced Polymer (FRP) products have become essential across industries due to their high strength, durability, and resistance to harsh environments. However, one of the most crucial decisions in manufacturing FRP components is selecting the right resin system. The resin not only binds the fibers but also determines how well the product performs under different conditions. In this blog, we’ll help you understand how to choose the best resin for your FRP products based on your application, environment, and budget.

What Is a Resin System in FRP?

A resin system is the matrix material in an FRP composite that surrounds and binds the reinforcing fibers, providing structural integrity and environmental resistance. The choice of resin significantly influences the FRP product’s chemical resistance, thermal stability, fire retardance, and overall mechanical performance.

Types of Resin Systems Used in FRP Products

1. Orthophthalic Resin (Ortho)

- Cost-effective and commonly used for general applications

- Moderate corrosion and chemical resistance

2. Isophthalic Resin (Iso)

- Improved mechanical and chemical resistance compared to Ortho

- Suitable for moderately corrosive environments

3. Vinyl Ester Resin

- Excellent chemical, thermal, and corrosion resistance

- Ideal for highly corrosive and industrial environments

4. Phenolic Resin

- Superior fire, smoke, and toxicity resistance

- Used in applications with stringent fire safety standards

5. Epoxy Resin

- High strength and adhesion properties

- More expensive, used in specialized applications

Key Factors to Consider While Choosing a Resin System

Corrosion Resistance: Choose a resin that withstands the specific chemicals your FRP product will encounter. For example, vinyl ester resins are best for aggressive environments.

Temperature Resistance: Consider the operating temperatures. Epoxy and vinyl ester resins typically handle higher temperatures better than ortho resins.

Fire Retardance: Select fire-retardant resin systems that comply with safety standards like IS, UL, or ASTM.

Mechanical Strength: Isophthalic and vinyl ester resins offer better load-bearing and impact resistance.

Cost-effectiveness: Balance performance with cost. While vinyl ester is more expensive, its durability can lead to lower lifecycle costs.

Compliance Requirements: If your industry has specific safety or hygiene regulations (e.g., food processing or transportation), choose resins that meet those standards.

Resin Selection Based on Application Area

| Application Area | Recommended Resin Type |

|---|---|

| Chemical Plants | Vinyl Ester Resin |

| Water Treatment Plants (WTP/STP/ETP) | Isophthalic or Vinyl Ester |

| Marine Environments | Vinyl Ester Resin |

| Architectural Applications | Orthophthalic or Iso Resin |

| Food & Beverage Processing | Food-grade Isophthalic Resin |

Vinyl Ester vs Isophthalic Resin: What’s the Difference?

| Feature | Vinyl Ester | Isophthalic Resin |

|---|---|---|

| Chemical Resistance | Excellent | Very Good |

| Mechanical Strength | High | Moderate |

| Cost | Higher | Moderate |

| Flexibility | Better | Less Flexible |

| Applications | Industrial, Chemical | General Industrial |

How IndiGrate Helps You Choose the Right FRP Resin System

At IndiGrate Composites, we understand that one resin doesn’t fit all. Our experts:

- Provide consultation based on your industry and usage

- Offer customized resin formulations

- Ensure compliance with international safety standards

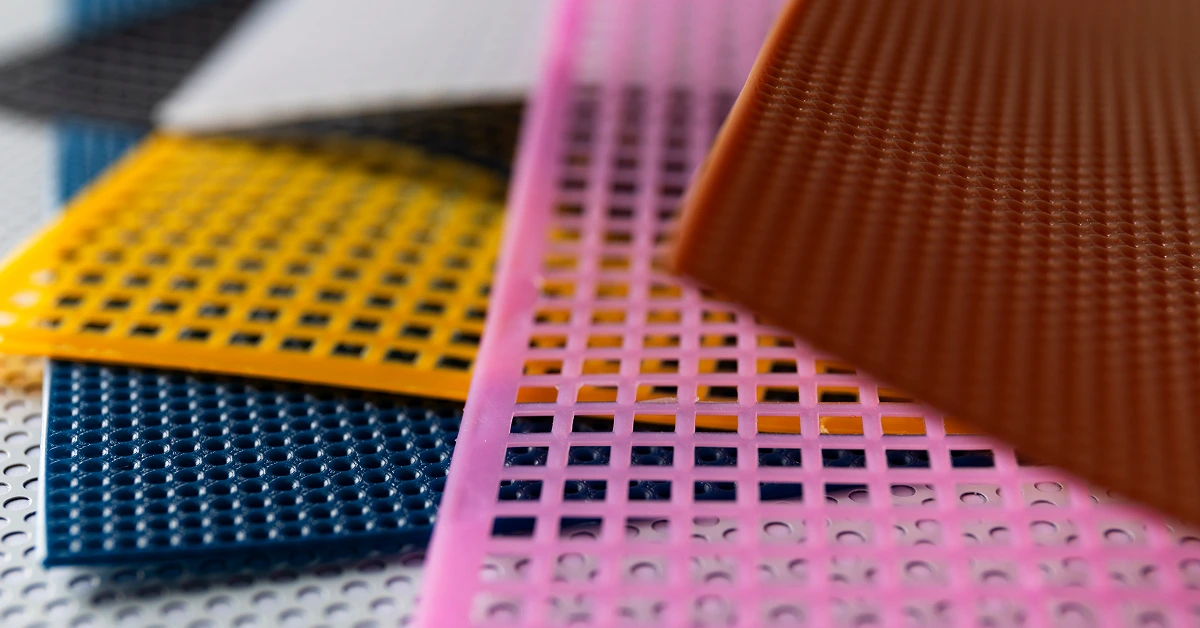

- Offer a wide range of resins and RAL color options to suit your needs

Frequently Asked Questions

What is the best resin for FRP in corrosive environments?

Vinyl ester resin is ideal due to its superior chemical and corrosion resistance.

How do I choose the right resin system for my FRP product?

Consider environmental exposure, temperature, fire safety, mechanical requirements, and cost. Consult with experts for the best fit.

What is the difference between orthophthalic and isophthalic resin?

Isophthalic resins have better chemical and mechanical resistance than orthophthalic, making them more suitable for industrial use.

Is fire-retardant resin available for FRP products?

Yes, options like VE-FR and ISO-FR comply with IS, UL, and ASTM standards for fire safety.

Can I use food-grade resin in FRP applications?

Yes, food-grade isophthalic resins are ideal for hygienic environments like food and beverage processing.

Conclusion

Choosing the right resin system is crucial for the performance, longevity, and cost-effectiveness of your FRP products. From understanding your application needs to evaluating environmental exposure and safety regulations, making the right decision upfront will save you time and money in the long run. Let IndiGrate help you make an informed choice.