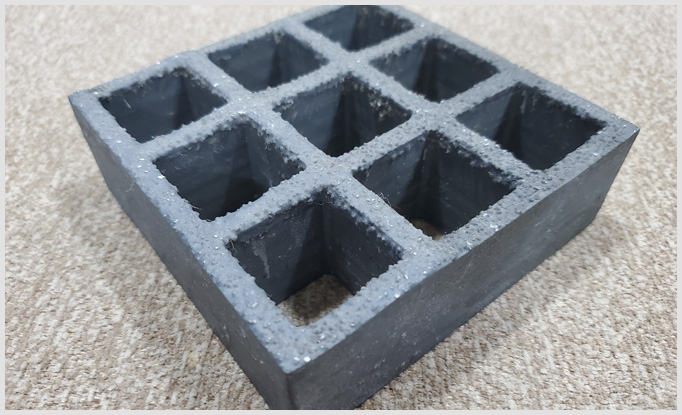

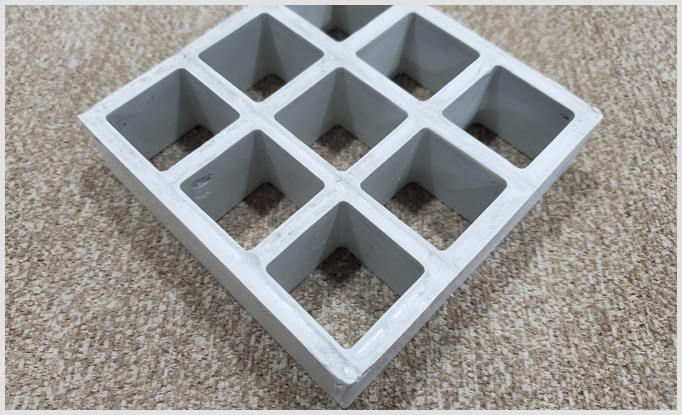

FRP Moulded Gratings

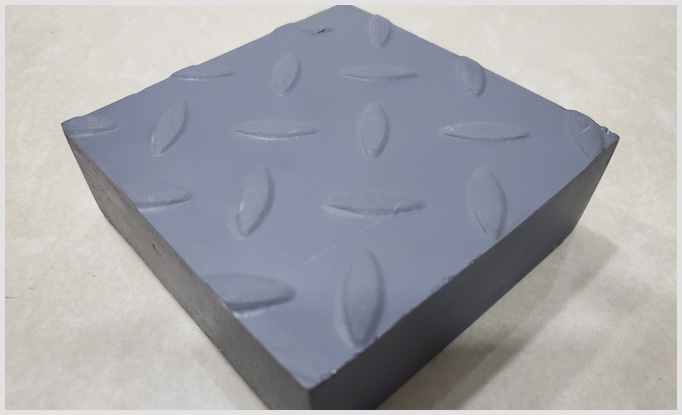

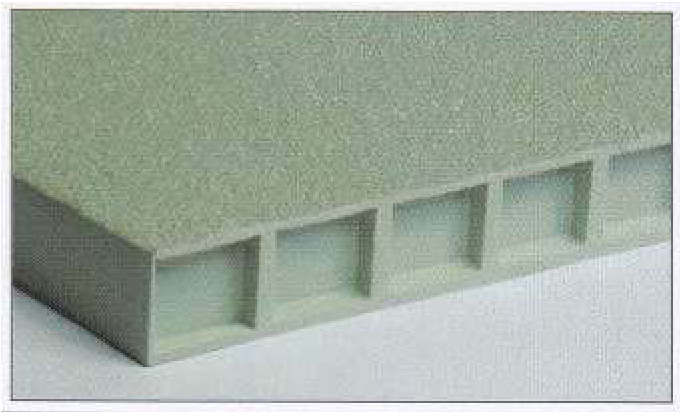

FRP Moulded Gratings provide a cost effective solution and long lasting performance for many industrial and recreational applications over a wide span of aggressive and corrosive environments. Owing to their excellent durability and long life span, these FRP gratings have completely revolutionized the entire industry where a traditional wood, concrete or metallic products tends to deteriorating rapidly. FRP molded gratings are available in a variety of resins, standard and custom colors, depths, panel sizes and mesh configurations. Surface options include a meniscus or integrally applied grit top, both of which offer superior, slip resistant footing. Our molded gratings are constructed in one-piece from continuous fibreglass rovings and a wide range of premium polyester or vinyl ester resins is used in place of traditional materials for a FRP solution that fits a wide range of applications and environments.

How We Make

Molded grating is manufactured by our skilled work force through manual hand lay-up in an open, heated steel mold. Continuous fiberglass roving is laid in the mold in alternating layers and thoroughly wetted out with the required polymer resin. This process involves constant monitoring of temperature control and curing cycle. This continuous process constructs a one piece panel that offers excellent corrosion resistance and bidirectional strength in both bearing and cross bars. Once cured the panel shall have a concave surface for slip resistance. A standard grit surface is made through a secondary operation by bonding grit to the grating panel. If the grating is to have embedded grit, the grit shall be applied during the curing cycle before the panel ejected from the mold.

Light weight

FRP's density is around 1.8g/cm3 which is about 1/4 of steel, or 2/3 of aluminium.

High Strength

FRP grating can be designed to cater for higher loads by reorientation and placements of glass fibers in various directions.

Corrosion Resistance

It is resistant to corrosion and has an inherent ability to resist chemical degradation usually caused by industrial gases and liquids.

Fire Retardance And Safety

Special Fire retardance properties based on IS, UL and ASTM standards can be provided to FRP Grating by selecting proper resin systems and formulations.

Easy Installation

FRP Grating being of lesser weight than other conventional materials such as GI, Steel, etc., will bear much lesser load on the supporting structure and also will be easier to transport and handle during installation.

long Term Cost Benefits

Compared with ordinary carbon steel, FRP grating has a lower life cycle cost owing to the non corrosive nature and its high strength properties.

Applications

- Platforms

- Walkways

- WTP / STP / ETP Area

- Stair Treads

- Cooling Tower Area

- Rooftop Walkways

- Trench Cover

Sizes

| SR. NO. | PANNEL SIZE (MM) | MESH (MM) | HEIGHT(MM) | RIB THICKNESS (MM) |

| 1 | 1220 ×3660 | 38×38 | 38 | 5-7 |

| 2 | 1220 ×3660 | 38×38 | 30 | 5-7 |

| 3 | 1220 ×3660 | 38×38 | 25 | 5-7 |

| 4 | 1220 ×3660 | 38×38 | 15 | 5-7 |

| 5 | 1220 ×3660 | 25×100 | 38 | 5-7 |

| 6 | 1007×4127 | 40×40 | 30 | 5-7 |

| 7 | 1007×4127 | 40×40 | 38 | 5-7 |

| 8 | 1220×3660 | 50×50 | 50 | 5-7 |

| 9 | 1220 ×3660 | TOP : 19×19 BOTTOM : 38×38 |

38 (28 + 10 Rib Height) | 5-7 |

| 10 | 1220 ×3660 | TOP : 19×19 BOTTOM : 38×38 |

25 (15 + 10 Rib Height) | 5-7 |

| 11 | 1220×4000 | TOP : 19×19 BOTTOM : 38×38 |

38 (28 + 10 Rib Height) | 5-7 |

Resin

| RESIN CODE | DESCRIPTION | RESIN BASE | CORROSION RESISTENCE |

| VE-FR | CHEMICAL PROOF FIRE RETARDANT | VINYL ESTER | EXCELLENT |

| VE-EFR | CHEMICAL PROOF EXTRA FIRE RETARDANT | VINYL ESTER | EXCELLENT |

| ISO-FR | INDUSTRIAL GRADE FIRE RETARDANT | ISOPHTHALIC | VERY GOOD |

| ISO | FOOD GRADE FIRE RETARDANT | ISOPHTHALIC | VERY GOOD |

| ORTHO-FR | ARCHITECTUAL GRADE FIRE RETARDANT | ORTHOPHTHALIC | GOOD |

Special requirements of phenolic grating to carter to stringent fire safety norms can also be produced upon request.

Color

Indigrate Composites supplies gratings in different shades and colors. Customer can select the color of its choice based on RAL shades or its equivalent.